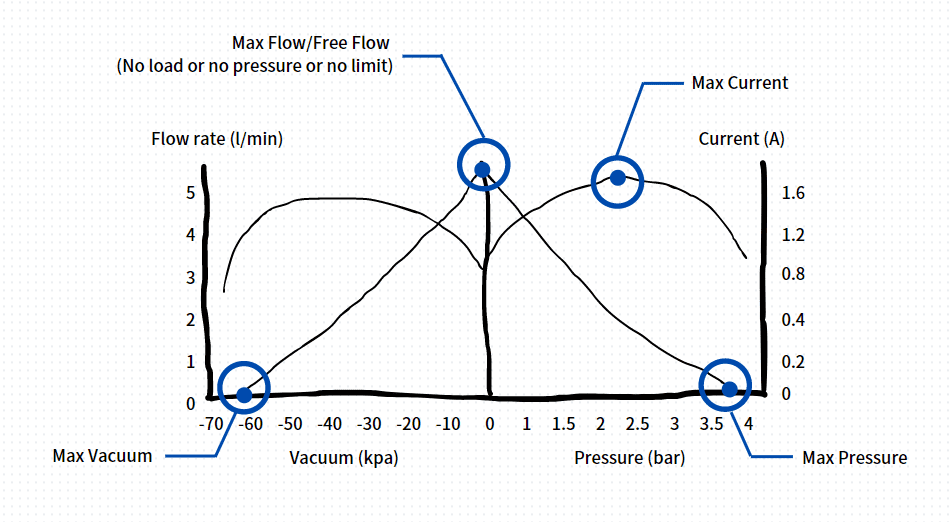

Understanding pump performance curves is vital in pump engineering and fluid dynamics. These curves provide a clear graphical representation of the relationship between different operational parameters of a micro air vacuum pump. This article explores three primary performance curves: the pressure-flow curve, the vacuum-flow curve, and the current-flow curve.

Key Elements of a Pump Curve

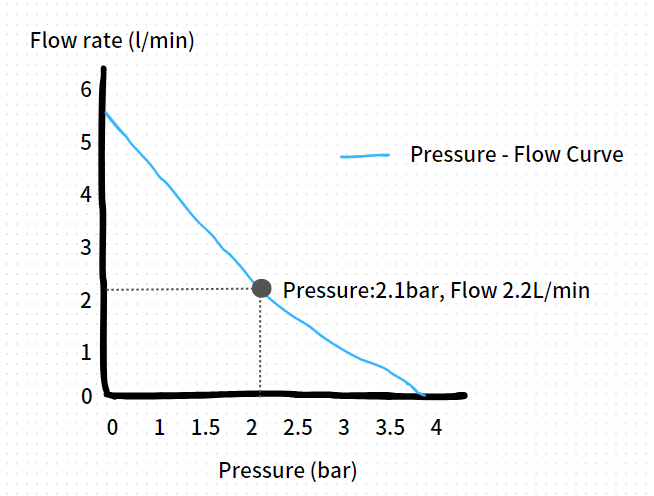

Pressure

Pressure in the performance curve represents the force the pump exerts to push fluid against resistance. It’s typically measured in kPa, bar, or psi and appears on the X-axis of the curve.

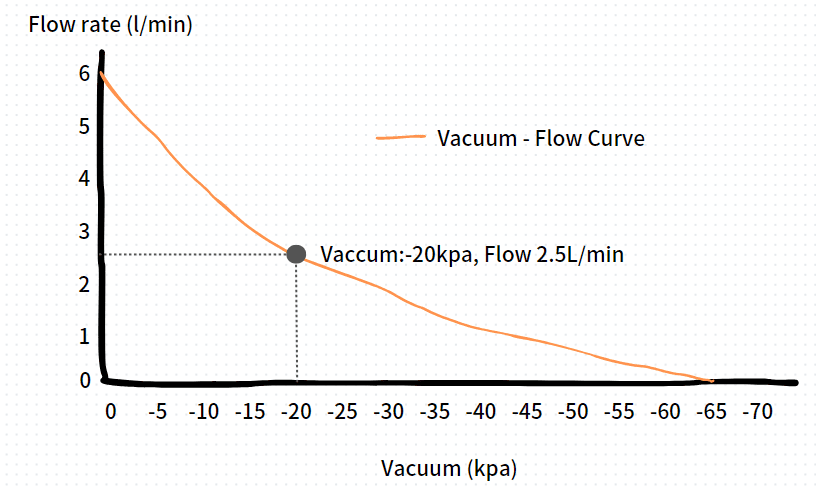

Vacuum

Vacuum measures the suction power of the pump, or its ability to draw in fluid during the intake cycle. Like pressure, it’s commonly shown in units like mmHg, kPa, or bar on the X-axis.

Flow Rate

Flow rate indicates the volume of fluid moved by the pump per unit of time, appearing on the Y-axis of the curve. This is usually measured in milliliters per minute (ml/min), liters per minute (l/min), or liters per hour (l/h).

Current

Current, typically measured in amperes (A), represents the electrical energy consumption of the pump, also plotted on the Y-axis in current-flow curves.

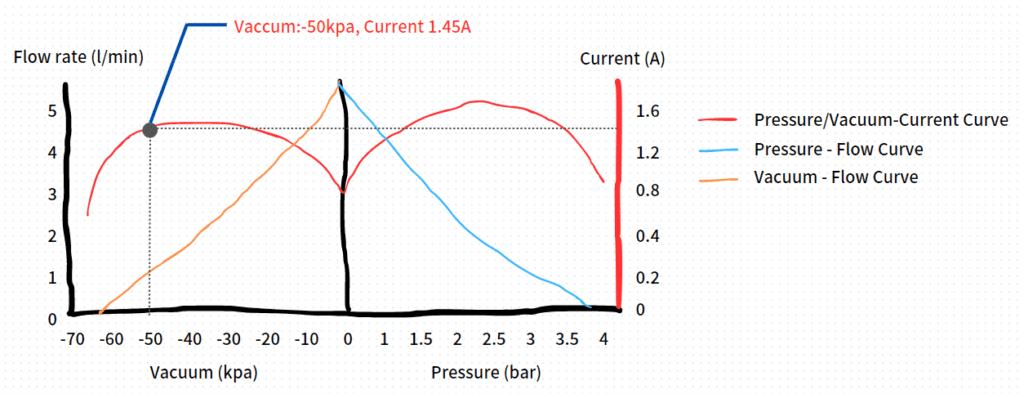

The Pressure-Flow Curve

The pressure-flow curve visually demonstrates a pump’s ability to move fluid under pressure. Pressure, usually on the X-axis, is plotted against the flow rate on the Y-axis.

Reading the Pressure-Flow Curve

As the flow rate increases, pressure tends to decrease due to the extra energy required to maintain a higher flow. This inverse relationship is typical for micro air vacuum pumps. The Best Efficiency Point (BEP) represents the most efficient operation point, where the pump provides an ideal balance of flow and pressure.

The Vacuum-Flow Curve

This curve shows the relationship between vacuum (X-axis) and flow rate (Y-axis).

Interpreting the Pressure/Vacuum-Flow Curve

Like the pressure-flow curve, this graph usually indicates an inverse relationship between vacuum and flow rate. As the flow rate increases, the suction power of the vacuum decreases, requiring more energy to handle the additional fluid volume.

The Current-Flow Curve

This curve highlights the electrical efficiency of the pump, relating pressure/vacuum to the pump’s current consumption.

Decoding the Current-Flow Curve

Generally, as pressure or vacuum increases, current consumption also rises. This happens because more energy is required to maintain higher pressure or suction. However, different pump designs, operating speeds, and fluid types can affect this relationship. Identifying the point at which the pump offers optimal performance with minimal electrical consumption is key to efficient operations.

Decoding the Pump Curve

Identifying the Best Efficiency Point (BEP):

The BEP is the ideal operating point where the pump runs most efficiently, usually at the widest part of the efficiency curve.

Finding the Operating Point:

The operating point is where the pump curve and the system curve intersect. This is the actual head and flow rate at which the pump operates in a real-world system.

Evaluating Power Consumption:

By examining the power lines in the curve, you can determine the pump’s energy use at different operating points, helping you select the correct motor rating.

Reviewing Pump Efficiency:

The efficiency curve provides insights into how efficiently the pump will operate at the designated operating point.

How to Read a Micro Air Vacuum Pump Curve

When analyzing a micro diaphragm pump performance curve, you’ll encounter critical parameters like maximum pressure, vacuum, flow rate, and current. Familiarity with these elements is essential to understand how the pump will perform under specific conditions.

The Importance of Pump Performance in Product Design

Pump performance is critical during product development, particularly for systems that require fluid transport or circulation. The pump’s ability to maintain the desired flow rate, pressure, and vacuum while using minimal energy significantly impacts the final product’s performance.

Pump Performance and Product Efficiency:

Pumps influence operational efficiency by delivering the required flow and pressure while minimizing energy consumption. Efficiency, in turn, affects the overall functionality of the product.

Energy Efficiency:

High-performing pumps ensure that the electrical energy consumed is efficiently converted into mechanical energy, reducing overall power consumption.

Role in Product Development Cycle:

Pump performance is essential during the design, prototyping, and testing phases. It ensures that the product will meet specified operational requirements while maintaining energy efficiency.

Connect with JSFLO – Your Trusted Micro Pump Manufacturer

JSG China high-flow micro pump manufacturer

As engineers at JSG, we are dedicated to providing superior micro pump solutions that align perfectly with your needs. We understand that pump performance plays a crucial role in product development and efficiency, and as such, our pumps are designed to operate at the optimal Best Efficiency Point (BEP) for energy efficiency and longevity.

With our extensive expertise in pump performance and the ability to interpret pump performance curves, we are perfectly positioned to provide you with the most suitable pump for your specific requirements. Our robust selection of high-quality micro pumps delivers the desired flow rate, pressure, and vacuum performance while ensuring maximum energy efficiency.

We invite you to reach out to us at JSG to discuss your pump needs. Our team of dedicated engineers and customer support professionals are ready to assist you in selecting the perfect micro pump, understanding pump performance curves, and ensuring optimal operation throughout the pump’s life cycle.

Trust in JSG, your partner for high-quality micro pumps designed with efficiency and longevity in mind. Contact infoadmin@dc-pump.com

Attach a link to this article: https://www.dc-pump.com.

Note: All content and images in this article are original creations of JSG For permission to reprint or use any articles or images, please contact the author.